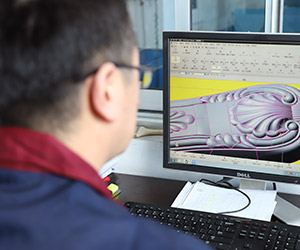

Moulds for Manufacturability

Mould is the key in the cutlery industry, which will decide the success of the latter product launch. For this, we make perfect moulds for perfect tableware.

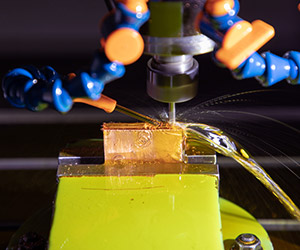

The industry-leading steel like Japan SKD11, US D2, and German 1.2379 steel are the only options of JOY's for mould, which allow for more heavy-duty possibilities on mould processing.